3D Reverse Engineering

Trying to understand the operation of devices or components without the original technical drawings? 3DLS can support you with reverse engineering. Without infringing on patents, we can use our advanced 3D scanners to analyze how a product behaves. With this information, you can reproduce the product or part.

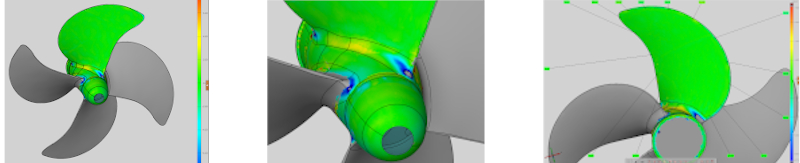

Even if no (accurate) drawings exist but a 3D CAD model is needed for engineering or production, 3D scanning offers a solution. Objects can be captured down to the millimeter in a point cloud and processed into a 3D CAD model using reverse engineering.

Complex shapes like ship propellers and hulls can be documented using 3D engineering for further development into parameterized CAD models or transformed into surface or solid models (e.g., in SolidWorks) using meshing.

Why Reverse Engineering?

Reasons to choose reverse engineering vary but often include:

- No technical drawings or 3D files available for an existing product

- Need to develop product documentation

- Parts or products are no longer available but still necessary

- Analyzing a competitor’s product

When an existing product is redrawn in 3D, it is also possible to explore improvements — related to production volumes, material development, and manufacturability.

Interested in Reverse Engineering?

Curious about how the 3D scanning process works or how it can benefit you? Schedule an appointment or give us a call with your questions.

Also, check out our other 3D scanning services and references in the automotive sector.

Read more...

Read more... Read more...

Read more...