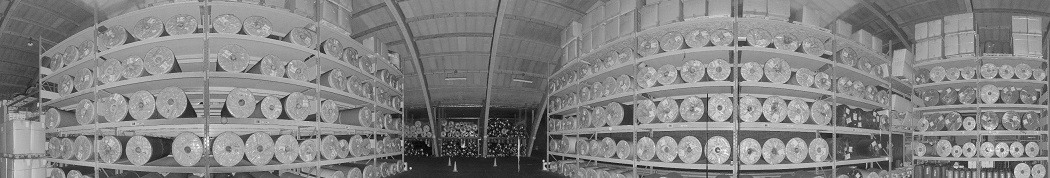

3D laser scanning warehouse Colbond

3D laser scanning warehouse Colbond

3D laser scanning warehouse Colbond

Colbond is a leading producer of high-quality synthetic nonwovens for applications in the carpet, automotive and construction sectors, as well as three-dimensional polymer mats and composites for civil engineering, construction and industrial applications.

The products are temporarily stored in a warehouse with an area of 20,000 m² and a high turnover rate. The goods vary in size and are only available for a short time. This requires being able to determine the available capacity quickly and accurately. In addition, local authorities want a current map i.v.m. among other things a nuisance law permit.

The entire warehouse is captured by 3D laser scanning within 2 days. The scans are connected to each other to form a model and from this, using Slicing the current map distilled. Serious deviations from the existing drawing came to light. With the available Faro Scene LT software, Colbond employees can view the scans (“3D black and white photos”), measure them and calculate the capacity from behind their desks.