Stork Pompen

3D laser scans leading the modernization of pumping station

3D laser scans leading the modernization of pumping station

“All puzzle pieces fall together”

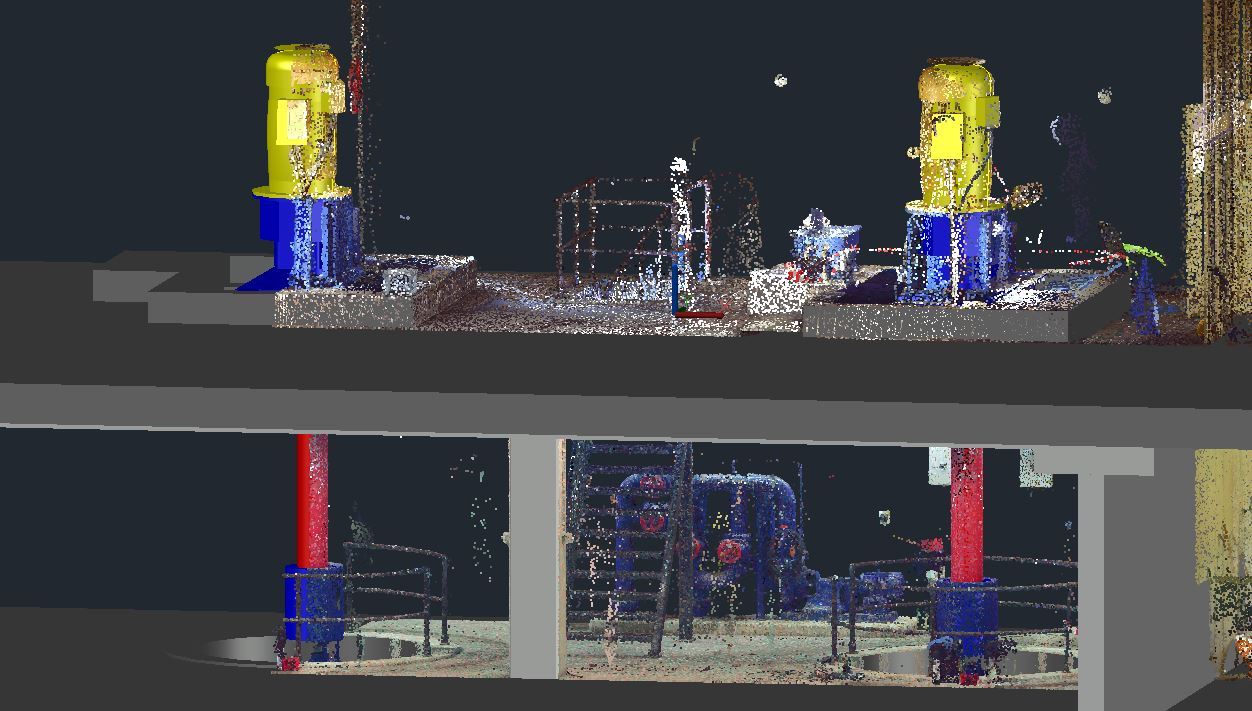

Stork Pompen is working on the radical modernization of the Spijksterpompen pumping station in Groningen. Due to the complex engineering aspects, with 3D laser scanning, Ergo-Design accurately mapped the pumps and pump housing of the pumping station

. “Thanks to the 3D scans, we already know on the design table what exactly is possible and how we can optimally fit new installation components,” says business developer Geert Hoeflaak. The 3D model also saves time in the engineering phase

The Noorderzijlvest water board has started a substantial expansion of the pumping capacity of the Spijksterpompen pumping station near Eemshaven in Groningen. Increasing the drainage capacity is needed to cope with the increasingly heavy rainfall caused by climate change and the consequences of subsidence. In addition to replacing the electrical and control systems, the two pumps are being radically renewed by supplier Stork Pumps and equipped with a completely new powertrain. The first pump has since been refurbished and successfully tested. After the wet winter season, it is the turn of the second pump in the spring of 2020. For the renovation project, Ergo-Design mapped the pumping station with 3D laser scanning one hundred percent accurately. “We often use Ergo-Design’s 3D laser scanning technology. They are among the leaders in this field. Because of the complex engineering aspects, we decided to do the same for this project, “says business developer Geert Hoeflaak van Stork. “Thanks to the 3D scans, we already know on the design table what exactly is possible and how that will turn out in the new situation. After all, we can make everything one hundred percent suitable. We can optimally connect new components, such as gearboxes and frequency converters. ”

The 3D laser scans enable the employees of Stork Pumps involved to visually study and measure the pump installations in photo quality. Employees who have not been on site also explain Ergo-Design’s 3D scanning specialist Kees Brugman. “Exact dimensions are also available for normally invisible parts of the installation. For example, the pumps stopped during scanning, so that we could also map the paddle wheel. The dimensions of this space are therefore also available. ”

Point cloud

The 3D scans from Ergo-Design not only serve as a basis for the prefab design of the new installation, but also ensure a smoother engineering in practice, says Hoeflaak of Stork Pumps. “Because the existing situation is accurately reflected in the 3D model, we can remotely design all technical installations to size. Our employees do not always have to go to the pumping station for that. ”Not only did the engineering phase go faster, but Hoeflaak also stated that implementation was much smoother. “We certainly had less work on the project for a few days. The 3D scans were also very useful for the interaction with our client. The employees of the water board were able to see at a glance what we meant. ”

Point cloud & 3D model